BehrTech Blog

5 Things to Look for in an IoT Network Management Solution

In a previous blog post, we have explored why network and device management is the linchpin of an IoT system. By streamlining device provisioning and authentication, network monitoring and diagnostics, alongside software maintenance and updates, it enables businesses to successfully manage the complexity of large-scale IoT networks.

Having said that, not all network and device management offerings are created equal. While sharing similar key functions as mentioned above, different solutions can significantly vary in terms of user experience and the flexibility to adapt to specific network requirements. Amidst the growing fragmentation of the IoT ecosystem, integrability and interoperability will be at the forefront of a future-proof solution. This week, we walk through five important considerations when looking into a network and device management option.

1. Modular, Platform-Independent Design

Even with the proliferation of SaaS and cloud-based services over recent years, businesses have come to realize that the cloud isn’t ideal for every IoT scenario. When latency, data privacy and compliance prevail, many would incline towards an on-prem deployment where data processing takes place locally within the company’s firewall. In many cases, a hybrid approach where workloads are divided between on-prem servers and public clouds is deemed optimal.

A versatile network and device management solution should cater to whichever deployment option you might end up with. Being platform-independent means that it can leverage the most modern infrastructure while allowing for easy migration from one computing environment to another. In parallel, a modular design where functionalities are loosely coupled provides the flexibility to deploy different software services on- or off-premises, independently from one another. With this, you can take advantage of a hybrid architecture to maximize your data potential.

You might also like: IoT Architecture – 3 Reasons Why Microservices Matter

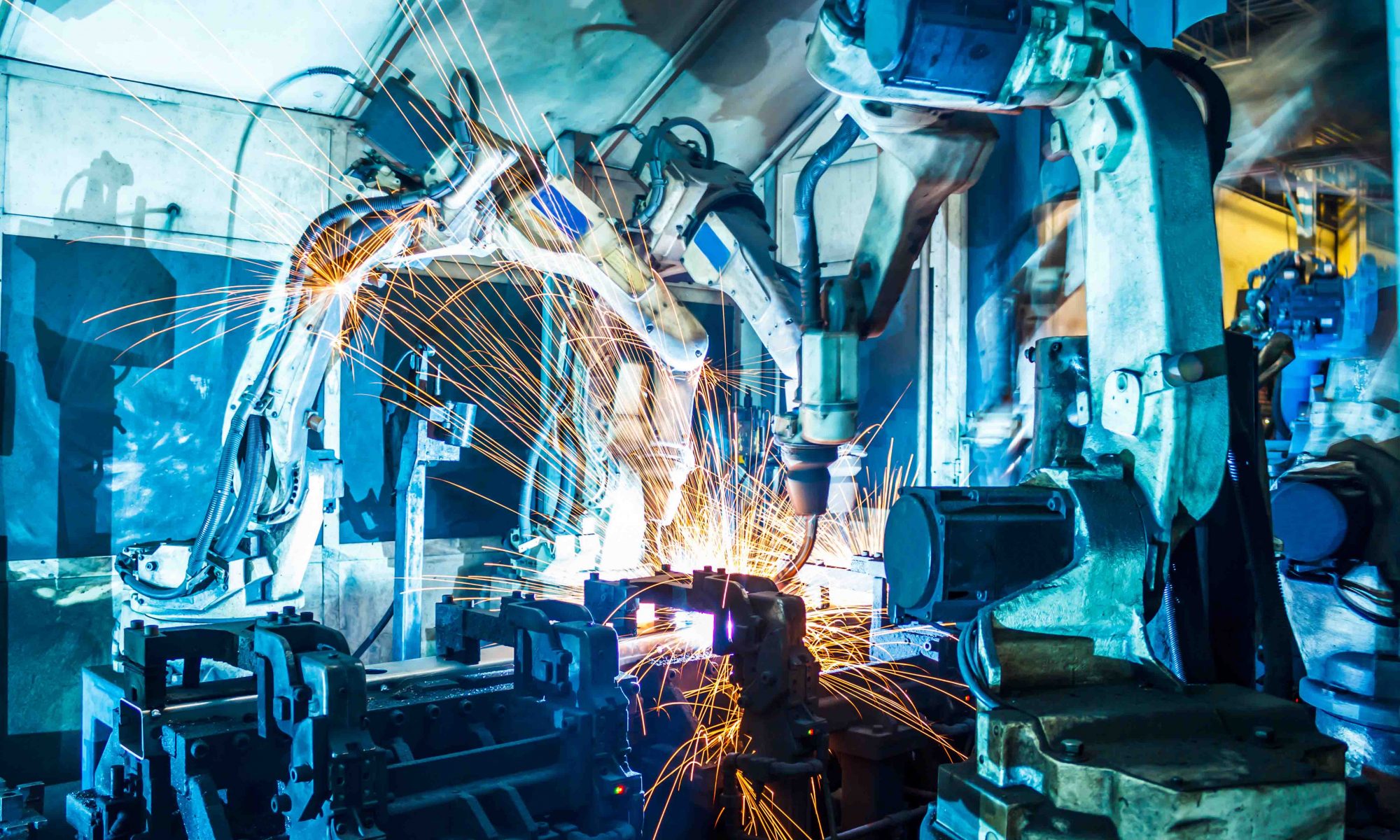

2. Cross-Vendor Device Compatibility

Today’s exploding number of hardware vendors has turned the smart device ecosystem into a highly complex landscape. For an IoT system to generate the most value, cross-vendor devices are required to effectively address multiple business challenges and use cases. For example, a smart building system may include occupancy sensors, environmental sensors and leak detectors, each of which is procured from a separate vendor. As the IoT landscape quickly evolves, seamless and straightforward integration of new cutting-edge devices is another prerequisite to sustain the viability and innovativeness of your connected system.

A solid network management solution is device-agnostic and offers a simple way to incorporate cross-vendor hardware models and data structures into the IoT workflow. Within a few simple steps, you can define the sensor model, payload type(s) and the unit(s) of measurements. This way, incoming data from diverse devices can be easily consumed and displayed in a user-friendly manner.

3. Open Architecture with Powerful Integration Tools

In unlocking business intelligence for enhanced decision-making, IoT data must be ingested into the enterprise systems and applications that are best-suited to derive its implications and suggest and automate the corresponding course of action. Each business has its own tailored applications and over time these applications will also evolve to meet changing needs.

An open architecture with modern interfaces allows data to be easily transported from end devices to any existing and future applications. While most device and network management software offer some sort of integration capabilities, the difference lies in their readiness, ease of use, and functionality. For example, REST APIs are a powerful and scalable tool for on-demand data requests, but you’ll need other API frameworks and protocols like gRPC or MQTT to enable real-time data streaming. A powerful solution delivers a rich set of APIs that can cater to every need, as well as robust native cloud connectors for minimal complications when integrating into leading hyperscale clouds.

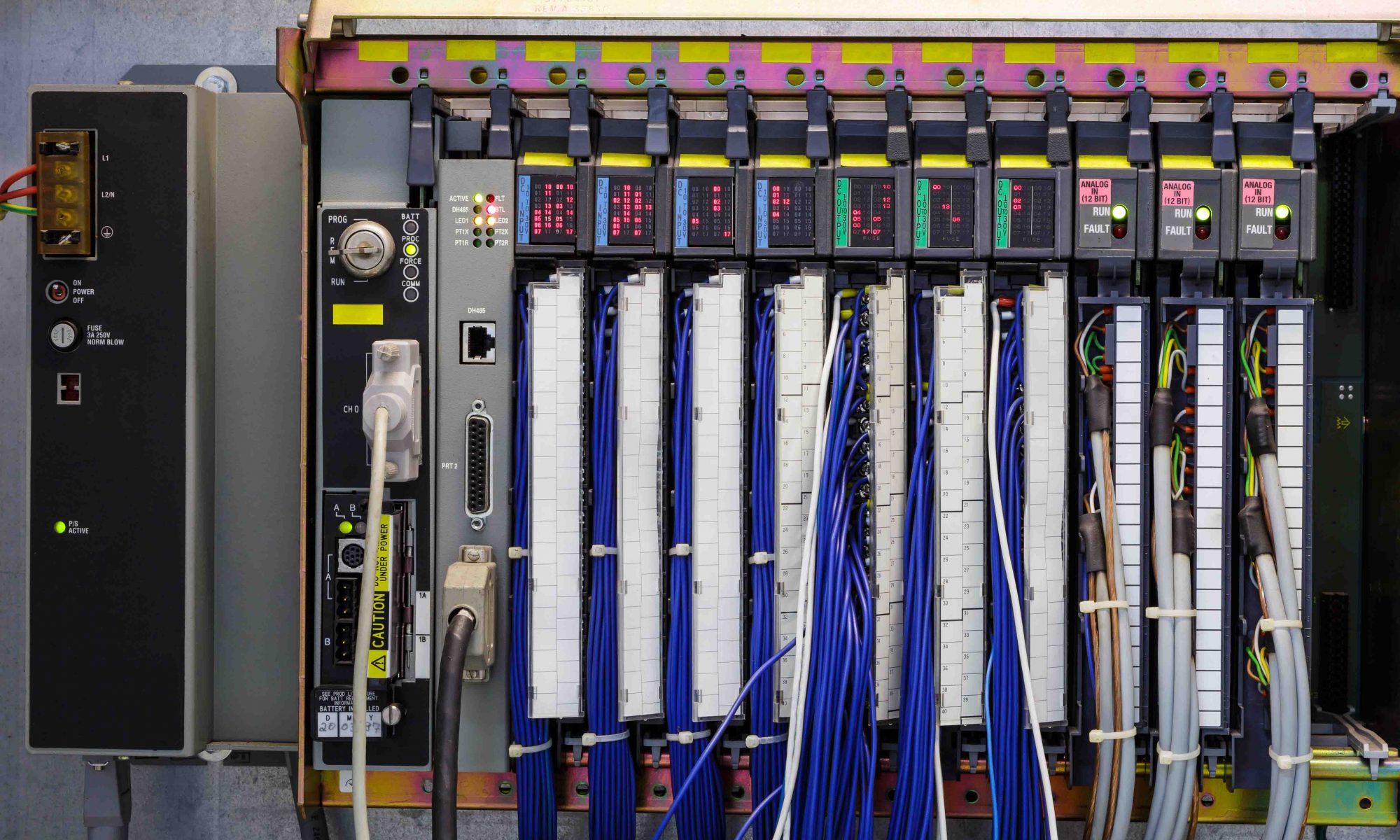

4. Built-in Security

Security must be thought out and embedded in every component in your IoT workflow. When it comes to device and network management, a top requirement is having all data traffic encrypted with industry-standard security protocols – be it from the base stations to the management server or from the management server to end applications. Typically, Transport Layer Security (TLS) is a proven choice for secure data communications between applications, servers and across the Internet. Equally important is making sure that robust API authentication mechanisms are supported, so connection attempts and data requests are only permitted for authorized client servers.

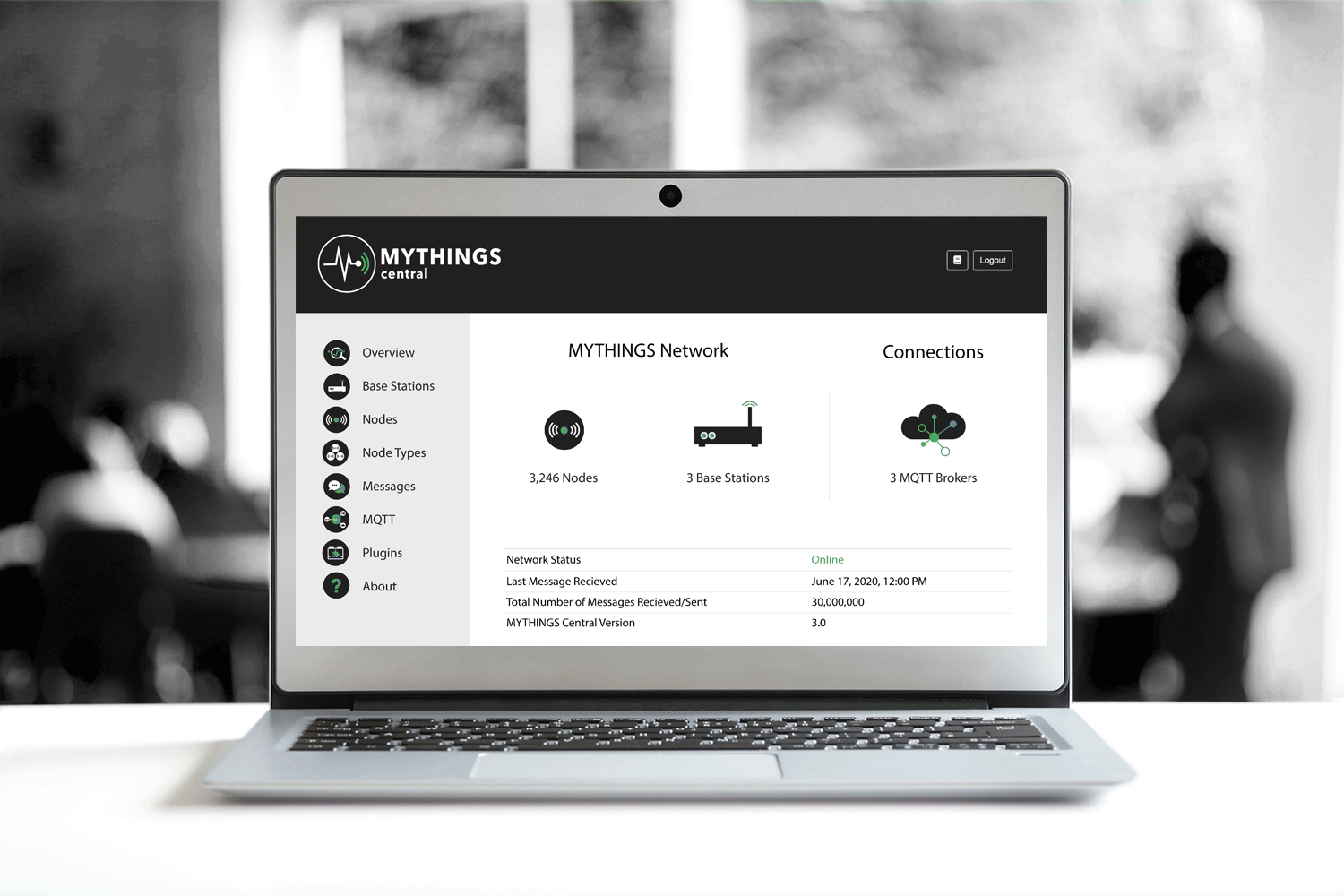

5. Intuitive, Customizable Management Portal/ UI

Even if REST API is available for integration and management from the user’s preferred interface, the network management solution should come with a clean, consistent and intuitive UI on its own. All functionalities like device management, data monitoring, network status information, and backend integration should be readily accessible and easy to navigate across the UI. Likewise, incoming messages should be updated in real-time and there needs to be an option for message filtering and data export. The most user-friendly solutions also make it easy to customize and white label the UI to the user’s branding as needed.

When bundled with a connectivity offering, a network and device management solution provides everything you need to get the network up and running, so you can focus on deriving your IoT data value and shorten time-to-market. The criteria discussed above are fundamental to validate the readiness and long-term viability of your chosen solution.

![[Product Webinar/> Inside MYTHINGS Central” title=”[Product Webinar] Inside MYTHINGS Central” ]</a><figcaption hidden=](|!|vcvUploadUrl|!|/2020/08/Webinar-social-1024x569.jpg)