BehrTech Blog

LPWAN and Environmental Monitoring: 5 Use Cases in Industry 4.0

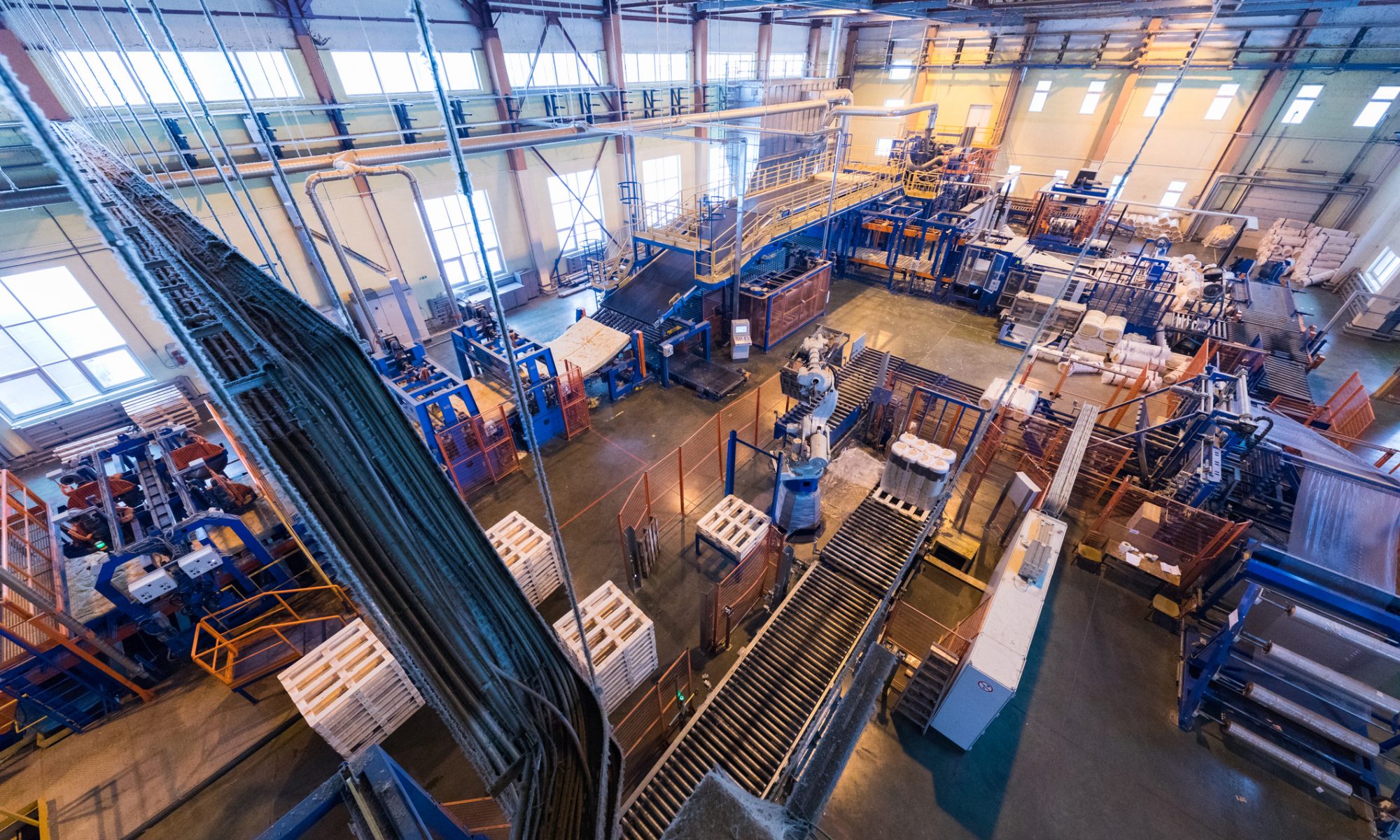

When talking about the Industrial Internet of Things (IIoT) or Industry 4.0, it’s not uncommon for manufacturers to interpret its value through the lens of factory automation. For many, a smart factory is a next-gen automation facility with advanced robotic equipment and enhanced real-time production control. High-bandwidth automation networks will have their place in the next industrial revolution, however they aren’t the only value creator. What’s most disruptive about IIoT is the ability to tap into unprecedented insights on the factory floor to optimize processes and boost productivity. And, a large part of these insights come from granular environmental wireless sensors.

Until recently, monitoring environmental conditions across industrial campuses had been prohibitive due to the costs and complexities of legacy wireless solutions. Environmental data is minimal in size, but the number of sensors needed to cover an entire facility is vast. Cellular and short-range solutions are too power-hungry and expensive for this type of low-bandwidth communications and therefore fail to scale with the required amount of end points.

Today, the advent of Low Power Wide Area Networks (LPWAN) introduces reliable and cost-effective connectivity for environmental monitoring. The technical design minimizes complexity and power footprint on the transceiver to lower device costs while enabling long battery life. Long range and a star topology additionally simplify deployment in large-scale, geographically dispersed facilities.

Environmental data delivers a whole new level of visibility into daily operations. By correlating contextual information with machine outputs and parameters, manufacturers can attain a holistic view of their production, identify bottlenecks and understand what is causing inefficiencies. Below are 5 examples of how LPWAN and environmental monitoring can help improve productivity and safety on the shop floor.

1. Quality Control

Ambient conditions have a significant influence on many industrial processes. For example, optimal air humidity and quality are essential for uniform coloring and painting tasks, alongside stable drying cycles and chemical reactions. Similarly, maintaining favorable room temperatures ensures precise fluid injections and optimal quality of 3D-printed components in industries like auto manufacturing. Having an environmental sensor network in place, manufacturers can oversee important ambient variables that impact production and respond timely to undesirable changes.

2. Worker Safety

Industrial workers are often exposed to a myriad of dangers. According to the International Labor Organization, work-related illnesses and diseases are estimated to incur USD$3 trillion of global economic losses each year. Monitoring workplace surroundings like air quality, combustible gases, heat, noise and radiation, can help better safeguard industrial workers. In conjunction with data from worker wearables, analysis of environmental data allows for identifying prolonged exposure to adverse conditions, out-of-tolerance incidents and potential workplace hazards. This enables managers to take counteractive measures accordingly to ensure worker’s health, safety and productivity.

3. Equipment Maintenance

A wide range of industrial and electronics equipment is subject to damage caused by unfavorable ambient conditions. Typically, excessive indoor humidity is conducive to condensation and corrosion of machinery, while too arid atmosphere leads to friction and electrostatic charge. Likewise, constant monitoring of the room temperature is vital to avoid equipment overheating that shortens its lifetime while presenting fire threats. Leveraging IoT sensors, businesses can have 24/7 insights into these critical environmental factors for effective regulation of heating and cooling devices.

4. Regulatory Compliance

In industries with treacherous extractive processes like mining, quarrying and oil and gas, rigorous environmental monitoring is integral in daily operations to minimize negative ecological implications. In this context, wireless sensors help automate monitoring tasks and deliver round-the-clock visibility to guarantee regulatory compliance. Specifically, they can report on underground water quality for early identification of acid drainage and prevention of widespread contamination. As another example, they can measure ground vibration, air quality and pressure during and after blasting to evaluate its impact on nearby residences and improve the future design.

5. Energy Management

Energy costs lie among the top operational expenses of industrial and commercial facilities. Despite the high overhead, statistics have shown that as much as 30 percent of the energy use is wasted. As companies constantly look to lower energy costs, granular IoT sensors offer an affordable approach to upgrade HVAC systems for higher efficiency. Instead of having a centralized and uniform HVAC setting, facility managers can leverage micro-zoned indoor climate data from IoT sensors to adjust heating and cooling on demand. Such a system helps circumvent the problem of HVAC overuse while optimizing occupancy comfort.

The power of IIoT goes far beyond what factory automation depicts. With ambient conditions having a significant impact on operational efficiency, safety and sustainability, IIoT is set to unlock this insight and open numerous opportunities to improve your business.

Subscribe to Our Monthly Blog Roundup